Build historic home with Interlock Bricks

Fly ash bricks are hi-tech well-improved quality bricks used for construction of brick masonry structures. When hydrated lime powder, gypsum are mixed and ground in a pan, the mixture gives a slow setting pozzalona cement. While the mix is pressed at low pressure at low moisture content in hydraulic machine, which is specially designed to give high pressure load at a slow rate, in the order of 350kg/square inch. At this of rate of pressure and with holding the pressure for a desired time gives ultimate strength to fly ash bricks.

Good Strength

Flyash bricks are stronger, more uniform, and denser than clay bricks

Eco friendly

Allows your business to take a step towards sustainable development

Reliable and long-lasting

The compressive strength is very high and they are less porous

The raw materials mix for the production of Interlock flyash brick

Flyash

M-Sand / Stone dust

Lime

Gypsum

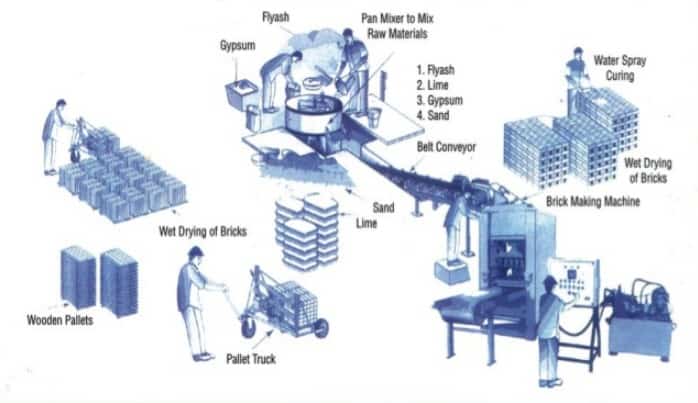

Manufacturing of Interlock Flyash Bricks

Fly ash, Lime, Gypsum and sand are manually feed into a pan mixer where water is added to the required proportion for homogeneous mixing.

The mixture gives a slow setting pozzalona cement. While the mix is pressed at low pressure at low moisture content in hydraulic machine, which is specially designed to give high pressure load at a slow rate, in the order of 350kg/square inch. At this of rate of pressure and with holding the pressure for a desired time gives ultimate strength to fly ash bricks.

Than the bricks are placed on wooden pallets and kept as it is for two daya there after transported to open area where they are water cured for 21 days to achive full strength. Finally bricks are sorted and quality tested before dispatch.

Advantages of Interlock Flyash Bricks

1. High compressive strength

2. High strength to weight ratio

3. Fly ash bricks are lighter and stronger than clay bricks

4. Dimensional accuracy through uniform shape

5. Low water absorption

6. Zero efflorescence

7. Consume less mortar in construction for joints and plaster reduces almost by 50%

8. Due to high strength, practically no breakage during transport and use

Watch Video

High compressive strength

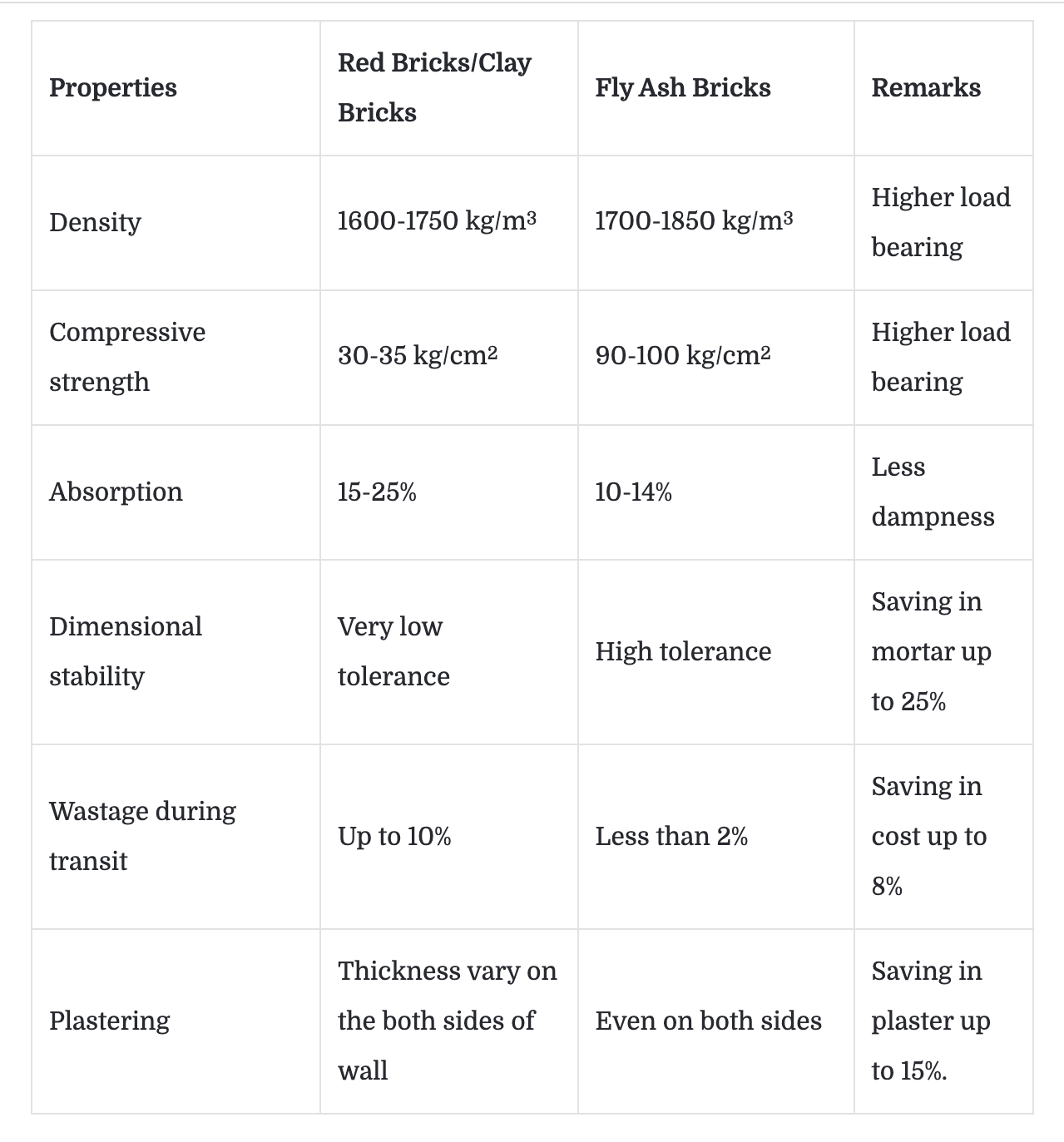

The Compressive Strength of fly ash Brick is three times more than the strength of red bricks or clay bricks. Clay bricks minimum compressive strength is 3.5N/mm2 which is much more smaller than the fly ash bricks i.e. 8-12 N/mm2.

Than the bricks are placed on wooden pallets and kept as it is for two days there after transported to open area where they are water cured for 21 days to achive full strength. Finally bricks are sorted and quality tested before dispatch.

Standared size Bricks

1. Standared size 9"4"3" inch

2. Dimensional stability

3. Saving in mortar up to 25%

4. Even on both sides

5. Saving in plaster up to 15%

Watch Video

Best support

After completing the payment, Your order will be delivered within 2 hours to 24 hours*.

Whatsapp support: +91 7806913131

Email: [email protected]

Whatsapp details

Build your historic home with us

Best Flyash Bricks Manufacture in Coimbatore, Tamilnadu, India

Build your dream home with our international standared quality Flyash Bricks